Let’s be honest: the days of handing out cheap plastic squeeze bottles are generally over. While there are certainly still great uses for this type of water bottle, in the current era of “emotional support water bottles,” people take their hydration far more seriously.

The right water bottle can be prime real estate. It sits on your client’s desk, goes with them to the gym, and travels in their car cup holder. But that only happens if the bottle is actually worth toting around. If it leaks in their laptop bag? Your brand is now the enemy. Not all water bottles deserve your logo.

Here is our no-nonsense guide to buying custom water bottles wholesale without pouring your budget down the drain (hint: copper vacuum insulation).

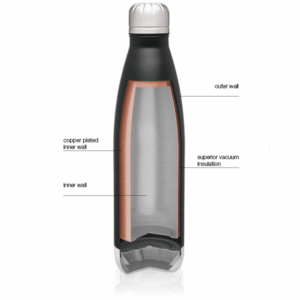

When you are looking at product images, everything looks similar. But you need to look past our amazing photos and consider way the bottle is built and the materials used to decide if it’s the right one for your needs. Here is the hierarchy of hydration:

- BPA-Free Plastic: The budget option. Great for 5k runs or massive trade shows where quantity rules. They’re also great for schools and sports teams.

- Aluminum: Lightweight and inexpensive. However, they dent rather easily, and they are single-wall, meaning they “sweat” (condensation). Nobody wants a puddle on their conference table.

- Tritan: A copolyester with a higher perceived value than other plastics and even aluminum. They are shatter, stain, and odor resistant and come in fun colors.

- Double-Wall Stainless Steel: The gold standard. This is the vacuum-insulated stuff that keeps water cold for forever. If you want your custom water bottle to replace the one they bought at the store, this is the only option.

- BONUS POINTS: You want to sound like a true insider? Ask about copper insulation. When buying custom water bottles wholesale, specifically vacuum-insulated ones, ask if it’s copper vacuum insulated. You can’t see it, but it makes a massive difference in thermal retention.

How you put your logo on the bottle determines how long your brand stays visible.

- Screen Printing: The standard method of printing on water bottles. You can generally print on one side, two sides, or as a wrap around imprint.

- Full Color Printing: Great for complex artwork, gradients, and more than one or two imprint colors.

- Laser Engraving: The premium choice. It removes the top layer of paint to reveal the stainless steel beneath. It is permanent. It will never fade, peel, or scratch. It says “high-end” immediately.

Don’t forget the lid! Screw-top, flip-top, straw, chug, handle/no handle—this is where user experience lives or dies. People want access to their drinks in different ways, so consider the lid type when deciding on your project. It shouldn’t be an afterthought.

Don’t race to the bottom on price. If you spend $4.00 on a bottle that gets thrown away, you wasted $4.00. If you spend $15.00 on a bottle that sits on a client’s desk every day for three years, you just bought thousands of hours of brand exposure for the price of a few lattes.

One last tip: try not to rush the decision. Ask us for a sample, then actually test it out. Use it for a week. Then, buy for utility, buy for durability, and buy something you’d actually want to drink out of yourself.